Door handles and locks are breeding grounds for bacteria and viruses. While this may be common knowledge to many of us, the level of contamination found in a study performed by the Worcester Polytechnic Institute is shocking. The study found 1,323 bacterial colonies were identified from just 27 door handles – an average of ≈ 50 colonies per handle. Compounding this risk even further is the fact that some viruses can survive multiple days on surfaces. The good news is that there are a multitude of door hardware options that can reduce these threats. Contact our team of certified door hardware experts at HSJ if you need hardware recommendations for your existing facility or new construction project. Here are just a few of the options that are available.

DOOR HARDWARE OPTIONS

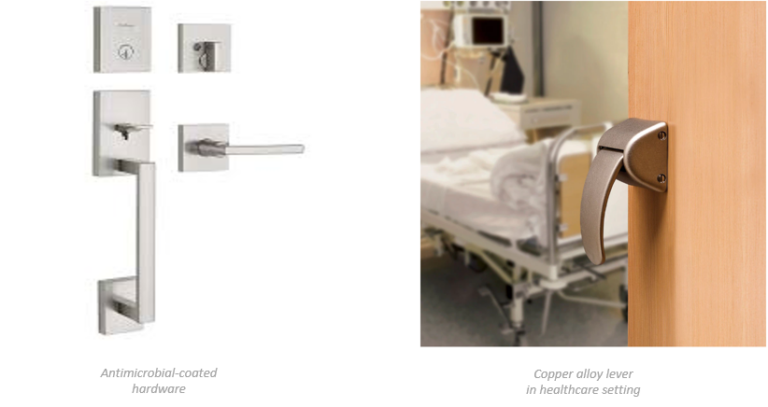

1. Anti-Microbial Solutions

Antimicrobial coatings are incorporated into levers and locks during the manufacturing process. When microbes come in contact with the treated surface, the cell wall breaks down and leaves the entire cell damaged, corrupting the integrity of the pathogen and leaving it unable to grow and reproduce. These coatings can be a applied to a variety of finishes to meet aesthetic and sanitary needs.

Copper hardware is another type of anti-microbial door solution. It is a naturally “biocidal” alternative, as it kills 99.9% of harmful microbes after just 1–2 hours of contact. It is only 25% more expensive than steel on average, and even less costly if combined with a lower-cost metal like a copper alloy solution. This option has the warm, gold/brown tone of its namesake.

2. Sheathed Handles

Sheathed handles provide a more sanitary solution verse standard door handles by dispensing an antimicrobial film to cover the handle for each user. Once the handle is touched and the door is opened, the used sheath is cycled into a separate compartment of the unit. This prevents cross contamination by using both a physical barrier with the sheath as well as antimicrobial properties on the device.

3. Arm-Pull Handle

Arm-pull handles are operated by using your forearm to pull the lever and open the door instead of your hand. They reduce the spread of bacteria by minimizing hand touches on levers but are not very intuitive for users since we are all so accustomed to using our hands to open doors. We recommend adding signage near the door to illustrate proper usage with the forearm. Without signage or training, people will often think the arm-pull handles are just awkward looking door handles and still open them using their hand.

4. Wave Actuators

Wave actuators open doors after being triggered by a “knowing action” like the wave of a hand. The knowing action assures that the door won’t automatically open if it simply senses a person passing by. This solution may be the most desirable of all due to the fact that they are touchless, don’t require disinfection as frequently, and can be operated intuitively by users. However, they are typically a more costly option since they require electro-mechanical hardware to be installed for operation.

5. Automatic Doors

Automatic doors use optical or motion detection to trigger the opening of the door when a user is sensed within a preconfigured distance from the door. They can also be triggered by card readers at secure facilities. You’ve most likely encountered these types of door solutions in grocery stores or large office buildings. They have numerous benefits but are more costly than standard self-operated doors.

6. Voice-Activated Access

Voice activation is becoming a primary mode of operation for many devices and doors are just another application of the technology. Similar to how Siri will find a restaurant near you or Alexa will tell you the weather, a voice activated command can open a “smart door” for you. Depending on the level of security desired, the door can be programmed to only allow access to specific voices it recognizes as authorized or to a specific phrase said by any user.

WHAT YOU MUST CONSIDER WITH DOOR HARDWARE

While these solutions provide value by greatly reducing cross-contamination of germs, there are factors you must consider when using them:

1. American Disabilities Act compliance guidelines must be adhered to when installing any operable door hardware. For example, handles and locks should be 34 inches minimum and 48 inches maximum above the floor or ground.

2. All door hardware must meet applicable NFPA codes/guidelines as well as any state and local life safety requirements.

3. Your hardware selection must be compatible with existing access control, fire alarm, and security systems to ensure life safety compliance and reliability.

Taking essential public health measures, like installing more sanitary door hardware can help save patients, employees, and businesses from dangerous infectious diseases. If you would like to learn more about adopting these solutions at your existing facility or adding them to a new construction project, please contact our certified team of door hardware and access control experts for a free consultation.