As door opening solutions become increasingly integrated into building and physical security designs, it is essential that the accurate specification, selection, installation, and commissioning of these subsystems are properly planned early in the design process to ensure that holistic building systems are fully functional and operational once constructed. As newer technologies are developed, customer requirements grow more complicated in suit, and design processes become more complex and collaborative. This is true for door, door hardware, and access control designs, as their installation and functionality become more correlated with and reliant on electrical, security, life safety, telecom, and energy management subsystems. This level of integration is the future of smart design and construction, but it also presents new vulnerabilities which, if materialized, can create substantial setbacks to project schedules, budgets, and customer satisfaction.

Lean methodologies strive to address and alleviate these vulnerabilities. While a debatable topic, the general definition of lean methodology is simply maximizing customer value while minimizing waste. Toyota originated these techniques with the Toyota Production System (TPS) which categorizes waste into eight (originally seven) categories: defects, overproduction, waiting, unused talent, transportation, inventory, motion, and over processing. The identification and minimization of these waste types focus on the reduction of unnecessary materials, resource allocation, or delays – essentially anything that does not create value. Managers and teams who are able to overcome these pitfalls end up being unsung heroes because avoidance is both proactive and preventative in nature, so their results are not readily able to be identified or quantified other than through meeting budgets, schedule adherence, and customer satisfaction, all of which are expected outcomes of a project.

Traditionally, lean principles are viewed as manufacturing and operational techniques, hence the oft-used terms “lean manufacturing” and “lean construction”, but by practically applying them during a design process, their consequences can be preemptively avoided by identifying lead indicators and monitoring requirement control limits. While the introduction of lean into any project or operational life cycle may seem exhaustive, the basic foundations of lean can be easily harnessed into any work process or value stream. The avoidance of wastes identified in lean methodologies is becoming more and more relevant for opening and access control components and subsystems as inaccurate design can make-or-break the final disposition and functionality of these elements within a building system.

The first layer of defense to prevent waste within a door and door hardware construction initiative is accurate design, thus avoiding the event that insufficient specifications and inaccurate requirements create trickle-down effects throughout subsequent procurement, construction, inspection, and commissioning phases. A detailed and proper design will avoid waste generation while meeting customer expectations, both of which are goals of lean methodologies. While considering this correlation between proper design and lean principles, consider the abovementioned trickle-down effect that can happen when the generation of these wastes occur.

The primary emphasis in door and access control design which can have the greatest effect on a lean project is product specification and selection. Defects in lean terminology has an all-encompassing definition of anything that does not meet customer expectation, and in a door opening design can include functionality (and possibly integration), code compliance, and aesthetics. The improper specification of non-electromechanical components of door opening solutions pose a basic vulnerability which can usually be identified once materials hit the ground at the construction site. Whether it’s frames or hardware which are not compatible with other building aspects, do not meet life safety requirements, or are not what the customer anticipated, these materials can be replaced – usually with cost and schedule ramifications. Electromechanical door and access control components pose a greater risk, as the integration with other building systems (i.e. electrical, telecom, security, etc.) may not be recognized until the final commissioning stages of a project. This can lead to extended schedules to troubleshoot issues, predicaments with Authorities Having Jurisdiction, or ultimately complete rework/reinstallation (motion). So, when designing a door hardware project, ensure that the level of detail is included in design drawings, hardware schedules, and specifications to allow for other disciplines to review compatibility, contractors have enough information to properly procure and install components, and customers have enough of a description to ensure their expectations are being met.

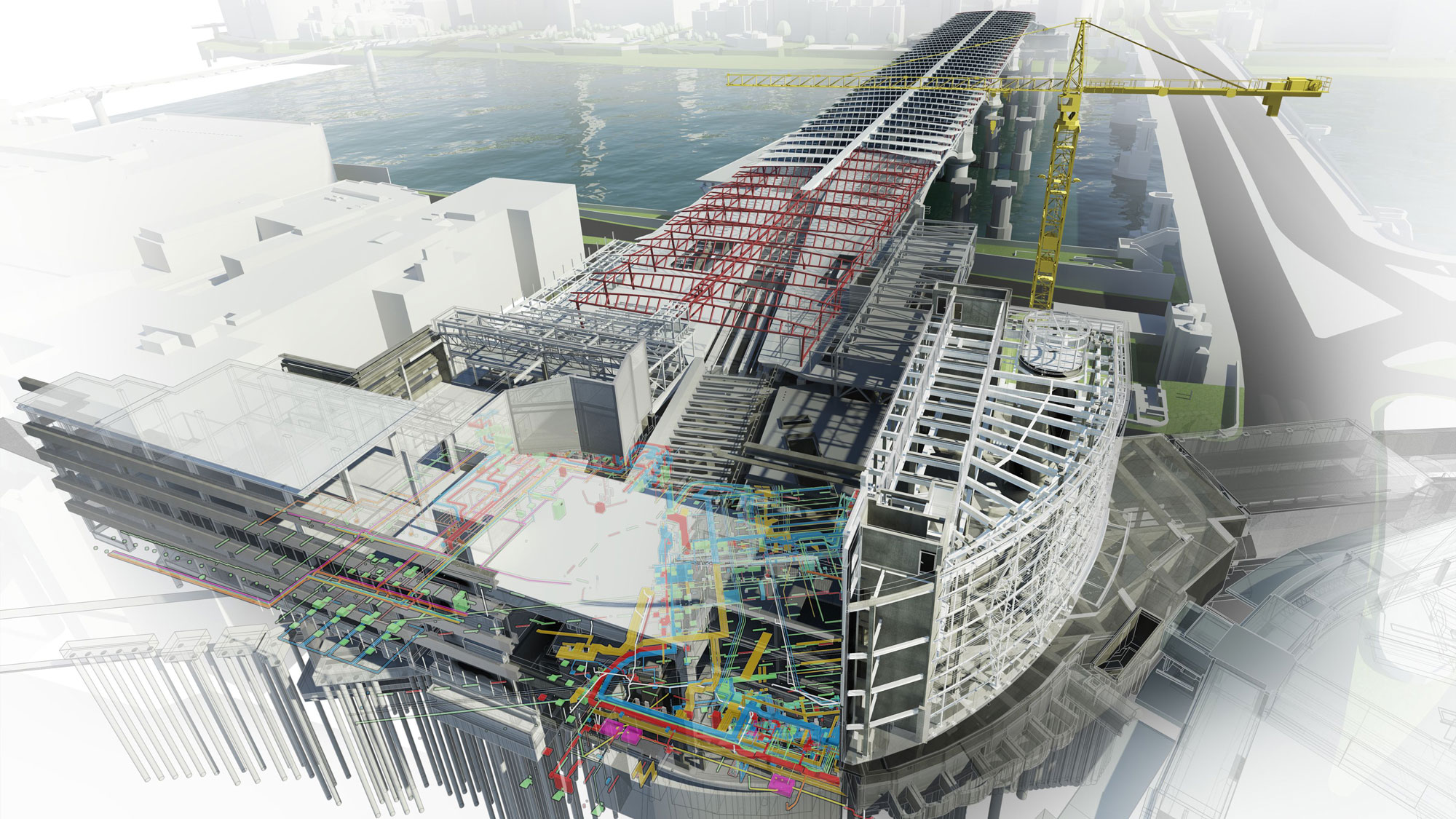

Quantification of all door hardware and access control components is vital when designing a construction or renovation project. Not only does the customer or contractor only want to pay for what is needed, inaccurate material quantification can lead to a number of interconnected waste types (the trickle-down effect). For contractors, over-conservative quantities can lead to manufacturers arbitrarily producing more product than required (overproduction), which leads to contractors ordering more than necessary (inventory), which can consequently result in return or restocking fees (transportation). Inversely, underestimated quantities can result in interruption of construction processes (waiting) and additional delivery costs (transportation). Obviously, accurate quantification of materials is essential for achieving a lean project. While BIM processes have assisted in the automated quantification of all door and access control components within a new design, renovation and re-keying projects are vulnerable to these quantitative waste types if precise surveys of existing conditions and requirements are not conducted.

Unused Talent (also called Non-Utilized Talent) is the newest lean waste type which was added after the seven types included in the original TPS and is waste generated due to not utilizing personnel with the skills or knowledge required to complete a task accurately or efficiently. While the traditional uses of lean techniques in construction and manufacturing references skilled labor, in a door opening and access control design process, this can imply employing a team member (or members) with the knowledge and skill to design, specify, oversee, and inspect hardware, components, and integration. Devoting an opening and access control subject matter expert early in the design project can alleviate several vulnerabilities, including ensuring that the voice of the customer is met without unnecessary quality or functionality costs (over processing). A door hardware subject matter expert can also be utilized for construction oversight, vendor management, and commissioning, all of which can continuously reduce waste throughout a project or process.

These lean principles and waste types can be applied and illustrated throughout an entire project life cycle, but with door, door hardware, and access control product and installation costs increasing in line with technological advances and integration requirements, the accuracy and precision of design and construction documents should be the primary focus of a team designing these elements. This is especially true in complex door and access control systems which are integrated and reliant on other building systems and coordinated with other disciplines, as waste grows exponentially with the size and intricacy of the undertaking. In effect, a proper design will inherently set the stage for avoiding waste throughout a project to ensure customer satisfaction – which is achieving “lean”.

© 2026 By H. Stephen Jones & Associates, Inc.

© 2026 By H. Stephen Jones & Associates, Inc.